NŪMOVE’S MONTREAL INNOVATION HUB!

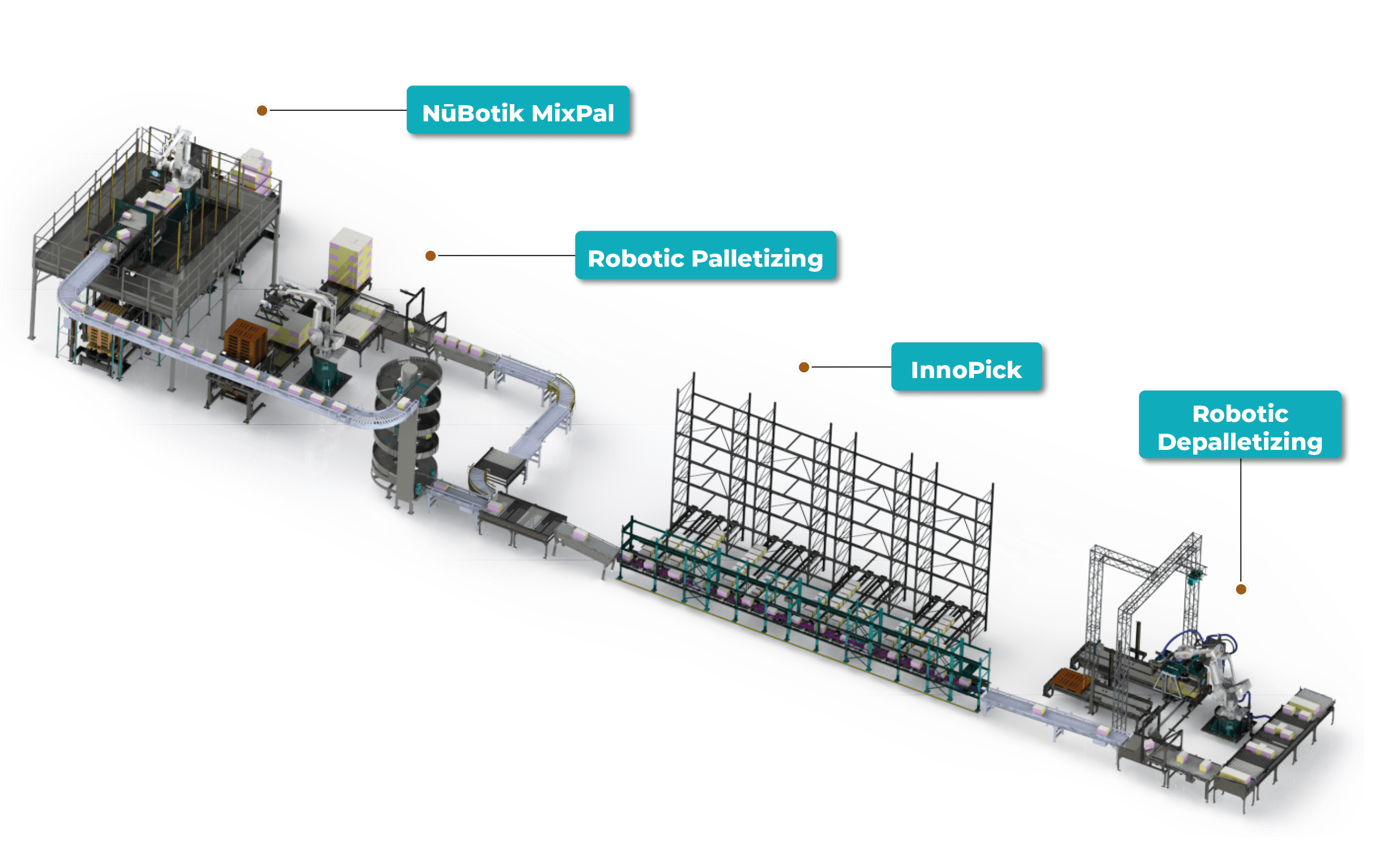

Discover NūMove’s Center of Excellence dedicated to automation technologies for warehouses and distribution centers. Located in Anjou (Montreal), this 20,000-square-foot innovation hub features a fully operational automation line that replicates the real-life journey of various products through warehouse and distribution environments. From robotic depalletizing and automated product storage to order fulfillment through robotic mixed palletizing, the center showcases end-to-end automation solutions in action.

WHY INVESTING IN A CENTER OF EXCELLENCE?

✔ Showroom for our warehouse solutions

✔ Customer visits & product demonstrations on request

✔ In-house testing & Innovation

A Large-Scale Project Unique in Quebec in the Field of Automated Warehousing!

Would you like to find out more or request a visit?

ROBOTIC MIXED PALLETIZING

NŪBOTIK MIXPAL

The NūMove Center of Excellence showcases our multi-SKU robotic palletizing solution, NūBotik MixPal, which features a robot on a 12-foot-high platform with an integrated wrapper. This is a highly attractive solution for warehouses and distribution centers, especially well suited to food and beverage products.

- This mixed palletizer can reach speeds up to 800 products per hour.

- Occupying minimal floor space, additional units can easily be added as production volumes increase.

- An advanced software is used to optimize mixed pallets, taking into account customer constraints and various stacking rules such as product type, dimensions, density, weight, crushability, etc.

FLOOR-LEVEL PALLETIZING

The Center of Excellence is also home to a second robotized palletizing system. This is a floor-level cell with an interchangeable robot tool, demonstrating the length of our expertise in end-of-line palletizing and warehouse automation technologies.

- We are able to offer mixed palletizing at a variety of speeds, either with our fork robot tool, which handles several products per layer, or with our other fork robot tool, which handles products individually.

- If required, we also have the option of demonstrating single SKU palletizing by layer, an automation solution aimed more at manufacturers than warehouses and distribution centers.

INNOPICK

We are also exhibiting a compact version of our InnoPick solution in the Centre of Excellence. This is a product storage and sequencing system (ASRS). This automation system guarantees efficient management of warehouse flows. Products are stored, and when an order needs to be prepared, InnoPick delivers the products to the palletizing station in an sequence predetermined by a software. In terms of capacity, the total number of products entering and leaving each level is 1400 per hour.

ROBOTIC DEPALLETIZING

At the entrance of distribution centers, pallets of products from manufacturers must be depalletized before the products can be moved to storage. This is where robotized depalletizing comes in! NūMove has designed several robotic depalletizing tools, and our Center of Excellence will be displaying one of them: a depalletizing robot that handles products per layer. Such an automation system can reach a throughput of up to 4 layers per minute.

VISIONARY PARTNERS

ABB Robotics is one of the world’s leading robotics and machine automation suppliers and the only company with a comprehensive and integrated portfolio covering robots, Autonomous Mobile Robots and machine automation solutions, designed and orchestrated by our value-creating software.

DRL Systems offers three cutting-edge automation solutions for order picking in distribution centers, tailored for high-moving products in trays, boxes or crates: InnoPick, a high-speed case dispenser, Mixmaster WCS software for streamlined operations, and a 2000 cs/h layer-based mixed-case palletizer.

Fabexp specializes in custom metal fabrication, from small welded assemblies to large-scale components, no matter the production volume.

Ryson International is the leading manufacturer of Spiral Conveyors in the USA. Ryson designs efficient vertical conveyors, such as Spirals and Bucket Elevators that require less floor space, catering to various industries including food, packaging and warehousing.

Founded in 1946 by Dr. Erwin Sick, SICK is a global leader in sensor-based industrial solutions, headquartered in Waldkirch, Germany. With 60 subsidiaries, 12,000 employees, and EUR 2.3 billion revenue in 2023 worldwide, SICK is a market leader in technological innovations.

STRATEGIC PARTNERS

ALLIED PARTNERS

FUTECH

MURRELEKTRONIK CANADA

Phoenix Contact

Schneider Electric Canada