In response to the growing need for interconnectivity in Industry 4.0 environments, we took the initiative to create our own software solution: NūLogik. This solution is fully developed and optimized in-house by NūMove’s software experts. Since existing market solutions did not fully meet our needs, NūMove created a flexible and customizable software designed to ensure seamless interconnectivity between our automation systems, third-party software, and the client’s environment. Accessible through an intuitive human-machine interface (HMI), NūLogik is integrated into all of NūMove’s automation solutions.

Explore the NūLogik Software Solution in Detail!

WHAT IS NŪLOGIK?

A Range of Functionalities Suited to Your Needs

First and foremost, our NūLogik software offers a broad range of capabilities. From simple data display to acting as a sophisticated coordination hub, NūLogik can be integrated at various levels within our automation cells. While it is designed to cover the full spectrum of operational needs, its implementation is personalized to each project based on the client’s specific goals.

Our software solution has the capability to function as the central intelligence of our automation systems. In this role, NūLogik orchestrates communication between the various physical and digital components of the cell, such as robots, PLCs, cameras, peripheral equipment, and more. One of the main reasons we developed our own software was to simplify integration with our technical modules. As a result, NūLogik can support a wide range of advanced features, including machine vision, autonomous palletizing recipe creation without additional programming, pallet optimization, and more.

Key Features of the NūLogik Software

- Industry-Specific Software: Purposely designed to meet the unique requirements of industrial automation and robotic cells.

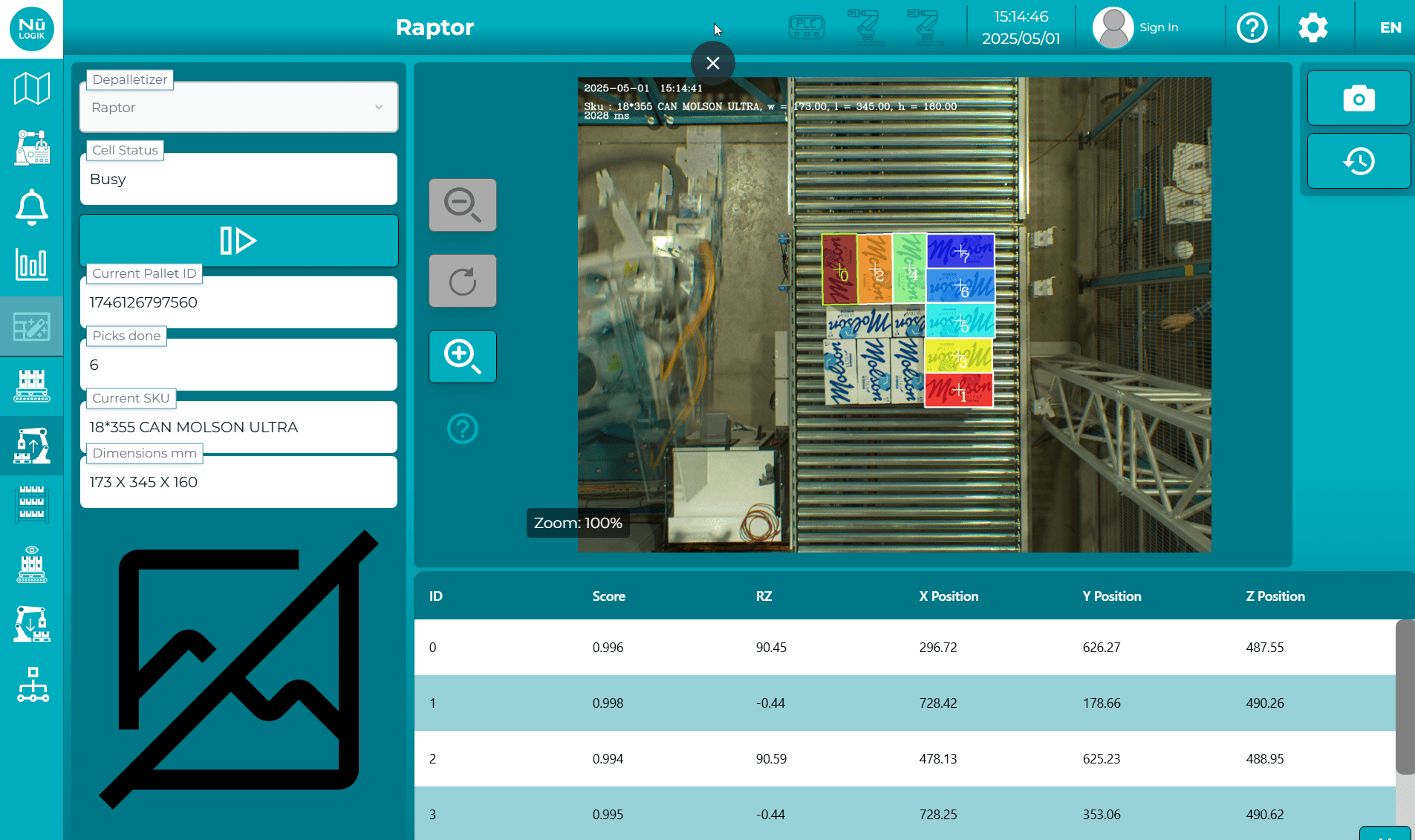

- User-Friendly Interface: Large, ergonomic touchscreen interface that provides clear visual information and empowers operators with high levels of autonomy.

- Connectivity & Simplicity: Easy to connect and integrate with clients’ existing systems.

- Standard Features: Real-time equipment and production management, advanced alarm reporting, and statistical data tracking.

- Advanced Features & Modular Design: Customizable features for each automation applications. Seamless integration of technical modules such as machine vision, artificial intelligence, autonomous palletizing recipe creation (no additional programming required), and pallet optimization.

- Support & Security: Integrated remote support service via a secure, encrypted router.

- Data Storage & Accessibility: Cloud connectivity enables data archiving, performance analysis through external platforms, and personalized support based on real-time logs.

- Software Updates: Smooth and secure deployment of updates ensures ongoing efficiency and continuous improvement.

- User Access Management: Secure user management system with customizable permission levels for each role.

- Multilingual Interface: Interface language available based on client’s preference. English, French, and Spanish are offered by default, with additional languages available upon request.

Interact with NūLogik Through an Ergonomic Human-Machine Interface (HMI)

Powered by our NūLogik software, the human-machine interface (HMI) provides operators with a simple and ergonomic way to interact with the automation system. Essentially, the touchscreen interface serves as the direct point of interaction with NūLogik for users. Screen display is fully customizable based on the nature of the system. While some tabs and sections are standard across most systems, additional modules and features can be added as needed. For example, when a solution includes machine vision, palletizing, or integration with third-party software, relevant tabs and functions can be incorporated accordingly.

Find Out More About our NūLogik Software Solution!