At the end of almost every manufacturing and packing lines of food, beverage and consumer goods,

products must be palletized to be shipped to either distribution centers or retailers. When multiple lines

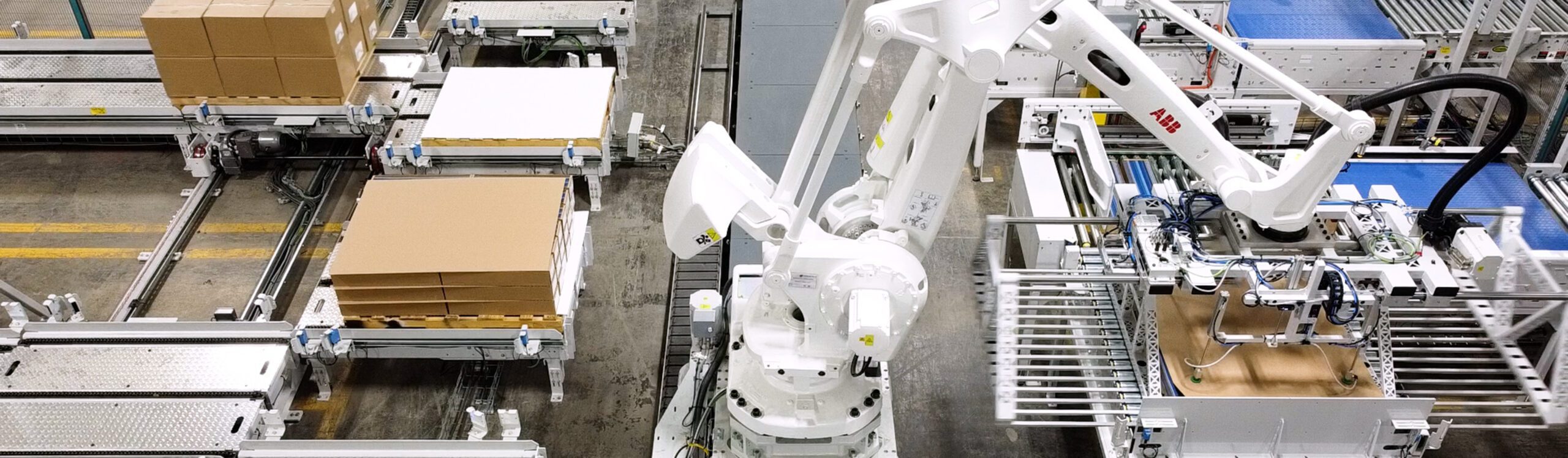

are side-by-side, two main robotic approaches are considered: a dedicated robotic palletizer for each line, or one robot that handles all lines. Based on previous projects, including one implemented in 2024 in North America, NūMove presents a case study on end-of-line palletizing.

This Case Study:

- Compares the traditional approach of implementing a dedicated palletizing robot at the end of each production line versus a single robot to handle multiple outfeeds.

- Explores when it becomes interesting to mount the single robot on a rail.

- Evaluates what motivates manufacturers to choose a single palletizing robot on a rail.

Read our Free Case Study

” In that situation, a palletizing robot on rail proves to be up to 20% less expensive per production line than dedicated robots. “

” Before the implementation of this robotic palletizer on rail, all customer’s lines were never simultaneously running at full speed. It is now possible! “

NūMove’s case study reviews the process that led a recent customer to choose a single palletizing robot on a rail. Check out our video below and take a look at the final solution analyzed in the document.