This blog post examines why robotics is solidifying its role as a cornerstone of supply chain innovation — as highlighted in the 2025 MHI Annual Industry Report — and what this means for 2026 and beyond. Drawing on insights from the report, we analyze how robotics addresses critical industry challenges and why it may continue to outperform even trendier technologies like artificial intelligence in real-world adoption.

As the logistics and supply chain industry continues to evolve under the pressure of labor shortages, rising customer expectations, and global disruptions, one technology stands out as a consistent driver of efficiency and resilience: robotics and automation. According to the 2025 MHI Report, robotics is not only among the most adopted technologies but also one of the most trusted to deliver long-term value and competitive advantage for 2026 and beyond.

Robotics: A Safe Value in a Volatile Industry

The report positions Robotics & Automation as a “safe value”, a mature yet evolving technology that continues to deliver measurable improvements in warehouse and distribution center operations. Despite the buzz around AI and blockchain, robotics has maintained a steady trajectory of adoption and trust.

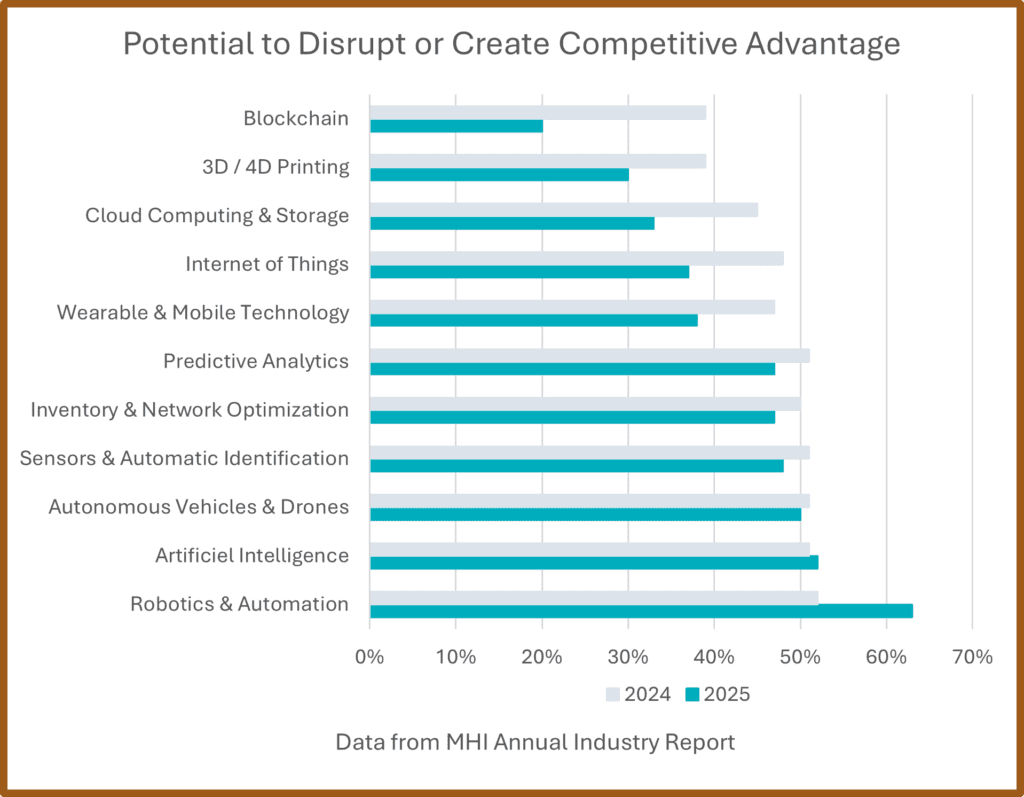

- 63% of respondents believe robotics has the potential to disrupt or create a competitive advantage, the highest among all technologies surveyed.

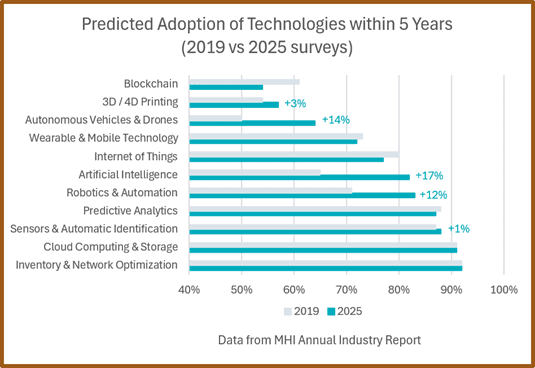

- 83% predict adoption within the next five years, placing robotics among the top five technologies for future investment.

This confidence is not just theoretical. Robotics is increasingly seen as a practical solution to persistent industry pain points, particularly those related to labor.

Addressing the Labor Crisis with Automation

What are the top two challenges in the supply chain industry? For several consecutive years, the same two issues have dominated the list:

- Hiring & Retaining Workers

- Talent Shortage

Together, these issues were cited by 97% of respondents as their most pressing concerns. There is no indication that this will change in the coming years. Robotics offers a direct response to this crisis by reducing dependency on manual labor and enabling 24/7 operations without compromising accuracy or safety.

As warehouses struggle to attract and retain skilled workers, robotic systems, from autonomous mobile robots (AMRs) to robotic picking arms, are filling the gap with speed, consistency, and scalability.

A Surprising Surge in Robotics Adoption in 2025

One of the most striking findings in the 2025 report is the 11% year-over-year increase in the perceived impact of robotics, a much larger jump than that of artificial intelligence, which only rose by 1%.

This is particularly noteworthy given that the Association for Advancing Automation (A3) reported only a 0.5% increase in robot sales in North America in 2024. The discrepancy suggests that while actual deployments may be lagging, industry sentiment and intent to invest in robotics are accelerating.

This paradox may be explained by the growing recognition of robotics’ long-term ROI, even if capital investments are delayed due to economic uncertainty or integration complexity.

How Does Robotics Compare to Other Emerging Supply Chain Technologies?

While technologies like blockchain, 3D/4D printing, and the Internet of Things (IoT) have seen declining interest over the past six years, robotics has remained resilient — as illustrated in the comparison table below. This stability underscores robotics’ maturity and reliability, especially when compared to technologies that have struggled to move beyond pilot phases.

| Technology | 2019 Potential to Disrupt | 2025 Potential to Disrupt | Change |

|---|---|---|---|

| Robotics & Automation | 64% | 63% | -1% |

| Artificial Intelligence | 55% | 52% | -3% |

| Blockchain | 41% | 20% | -21% |

| Internet of Things (IoT) | 52% | 37% | -15% |

Why Robotics Outpaces AI in Practical Adoption?

Despite the hype surrounding AI, the report reveals a surprising insight: AI is not yet perceived as significantly more impactful than robotics. In fact, many respondents view robotics as more immediately applicable to their operations.

Several reasons explain this:

- Maturity: Robotics technologies are well-established and have proven track records in logistics environments.

- Integration: Robotics systems can often be integrated with existing infrastructure more easily than AI platforms.

- ROI Clarity: The return on investment for robotics is easier to quantify, especially in labor-intensive processes like picking, packing, and sorting.

That said, the convergence of AI and robotics such as AI-powered vision systems or predictive maintenance is likely to enhance both technologies’ value in the coming years. Integrating AI into vision-guided robotic applications provides easier adaptability when new products are introduced or when their graphics change: no programming is needed as the AI algorithm can learn by itself to recognize those new products. We should therefore witness more applications integrating robotics and AI in a predictable future.

How Has Robotics Momentum Evolved Over Time?

Based on the data provided in this year and past years’ reports, we prepared some compelling charts that illustrate robotics’ rise in both perception and predicted adoption. These visuals reinforce the narrative that robotics is not just a trend — it’s a foundational pillar of the modern supply chain.

One key chart shows the year-over-year increase in the percentage of respondents who believe robotics will disrupt industry.

Another chart highlights the predicted adoption rates of various technologies over the following five years, comparing 2019 and 2025 results.

We can observe that only three technologies, and robotics is one of them, experienced significant growth for this time period.

Looking Ahead: What to Expect from Robotics in 2026 and Beyond?

As robotics enthusiasts, we’re eager to see how this industry will evolve in the coming years. Several trends are likely to shape the future of robotics in logistics:

- Greater integration with AI for object recognition and decision-making.

- Expansion into mid-sized and smaller warehouses, driven by lower costs and modular solutions.

- Focus on sustainability, with robots helping reduce energy consumption and optimize space utilization.

Conclusion

The 2025 MHI Annual Industry Report confirms what many in the logistics sector already know: robotics is not just surviving, it’s thriving. As companies grapple with labor shortages and rising operational complexity, robotics offers a proven, scalable, and increasingly intelligent solution.

While AI and other emerging technologies continue to evolve, robotics remains the most trusted and widely adopted tool in the supply chain toolbox. For organizations looking to future-proof their operations, investing in robotics is not just a smart move, it’s a strategic imperative.