This article was written for Tissue World Magazine by NūMove as a thought leadership piece on end-of-line automation. It explores how high-speed robotic palletizing solutions help tissue product manufacturers overcome SKU proliferation challenges while improving efficiency in modern production environments.

Why Does SKU Proliferation Create an Urgent Need for Automation in the Tissue Industry?

In today’s tissue industry the proliferation of SKUs — from 1-, 2-, or 3-ply formats to cube boxes, flat packs, and soft wraps — is reshaping production demands for facial tissue. Consumers are driving this change, seeking softer, stronger, and more absorbent products in increasingly varied formats.

SKU proliferation demands greater flexibility for automation as production lines need to manufacture various products in smaller batches.

To keep up, converting equipment has become faster. End-of-line automation, particularly palletizing, must also evolve in tandem to avoid bottlenecks and maintain throughput.

How We Engineered a Robotic Palletizing Solution to Deliver Both Speed and Flexibility

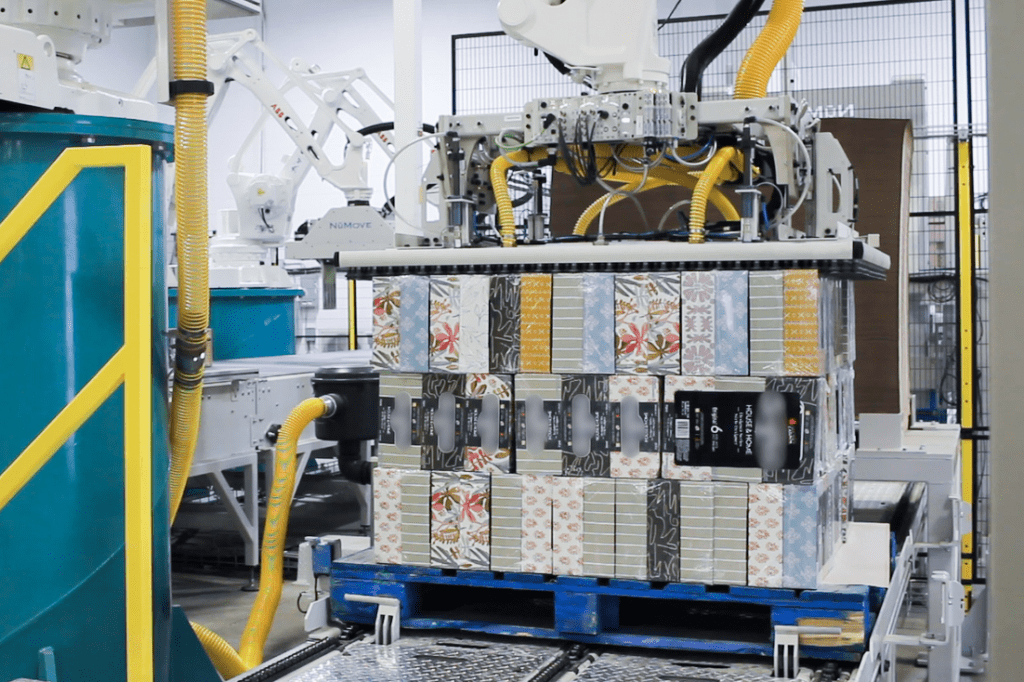

NūMove’s latest robotic palletizing system that was designed for a new facial tissue facility handles up to 100 distinct SKUs. The system achieves a throughput of 50 products per minute at 80% capacity.

This performance is made possible by a multi-robot configuration:

- Two side-by-side robots prepare palletizing patterns.

- One robot handles complete layer palletizing.

How Do Robotic Systems Adapt to the Wide Variety of Packaging Formats in Tissue Production?

Facial tissue secondary packaging varies widely — corrugated boxes, shrink-wrapped cartons, and loosely wrapped packs. The latter are particularly challenging due to their tendency to swing during robotic handling.

The end-effectors are then purposefully designed to address this.

- Pattern maker robots incorporate flexible clamps that adapt to product dimensions without causing damage.

- Palletizing robot incorporates multiple vacuum zones to accommodate gaps in palletizing patterns. This tool uses machine vision for layer validation, ensuring all products are within expected boundaries before palletizing.

What Are the Advantages and Limitations of Mechanical Versus Robotic Pattern Makers?

Since the products are handled in full layers when being palletized, product patterns must be prepared upstream. Two technologies were evaluated:

Mechanical Pattern Maker

For this application, two mechanical pattern makers are needed to meet the 50 products per minute rate. Below is a short description of how it works.

- Product are fed through two separate infeed conveyors

- If needed, products are turned 90 degrees as per the final pattern requirements

- Rows of products are built and indexed into the layer pick conveyor

- When completed, the full layer is picked by the robot

While the system benefits from a well-established and proven technology, its operational limitations must be considered. With a throughput restricted to 25–30 products per minute per unit, a wide physical footprint, and limited flexibility, it may not meet the demands of high-speed or space-constrained tissue production environments.

Robotic Pattern Maker

Another option is to use a dual-robot approach:

- Products are fed through one infeed

- The two robots share the work and rotate, or slide products as needed to prepare the layer

- The full layer is built at the end of the conveyor

- When completed, the full layer is picked by the robot

This approach offers advantages in speed, flexibility, and spatial efficiency, making it particularly attractive for tissue manufacturers seeking compact and agile automation solutions. However, these benefits come at a cost: the technology typically requires a higher capital investment and involves more complex programming, which may demand a specialized expertise during integration and maintenance.

Robotic pattern makers can operate blind if product feeding is controlled; or use machine vision for guidance. Robot programming must account for orientation needs, collision avoidance, and fallback scenarios where one robot takes over if the other fails.

See the Results of a Fully Robotic Approach

Watch this short video to see our robotic layer palletizer in action, featuring robotic pattern makers designed to deliver the speed and efficiency our customer required.

How Does NūLogik™ Software Enhance Flexibility and Adaptability in Robotic Palletizing Systems?

One of the standout features of this robotic system is its software-driven flexibility, powered by NūMove’s proprietary software named NūLogikTM. Operators can add new products without any programming via a step-by-step wizard on the interface. This eliminates the need for tooling changes or code updates. In an industry where product innovation is frequent and format diversity is growing; such flexibility is essential.

What Is the Market Outlook for Tissue Products, and Why Is Flexible Automation Now a Strategic Necessity?

Industry analysts project continued growth in the facial tissue segment, driven by demand for premium and customized products. This trend underscores the need for flexible automation that can adapt to frequent SKU changes and format innovations.

A robotic high-speed palletizing solution aligns with broader industry shifts toward smart factories and warehouse automation. Across the tissue industry, automation has evolved from a competitive advantage to a strategic necessity — enabling manufacturers to streamline operations, reduce labor dependency, and respond faster to market demands.

Conclusion

This high-speed robotic palletizing system sets a new benchmark for end-of-line automation in the tissue industry. Combining mechanical precision, software intelligence, and operational flexibility, it meets the evolving demands of modern production lines. In an environment where speed, SKU diversity, and adaptability are paramount, NūMove delivers a scalable, future-ready platform that empowers tissue manufacturers to stay ahead of the curve — today and tomorrow.