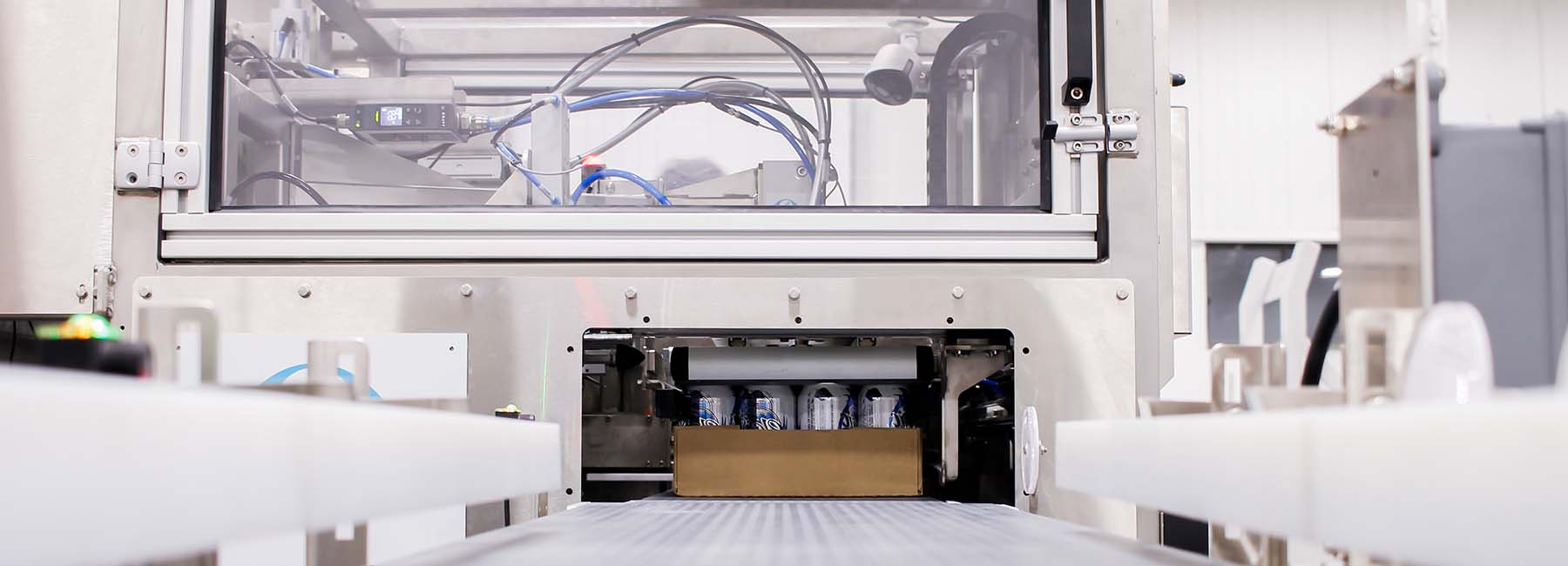

Our Uncasing System is the perfect equipment to integrate to your variety pack production line. As you may guess, this automatic can decaser unloads beverage cans of all sizes from trays. Then, cans are placed back on the main conveyor while empty trays are ejected into a tray outfeed conveyor.

Features

|

Would like to learn more about our uncasing system?

NūMove’s integrated equipment of the solution

NūLOGIK

NūMove is proud to have developed its own operator interface (Human-Machine Interface, or simply HMI). Why did we bother, you may ask? Well, NūLogik is designed by our software development specialists so it can be adapted to robot cells and easily integrated to our vision systems. In addition to its user-friendly characteristics, we can assure you NūLogik is customizable according to your needs.

- Developed specifically for industrial automated equipment with Industry 4.0 functionalities in mind.

- Production statistics improve operator efficiency and provide decision makers valuable information.

- Display of alarms for each equipment: fast process to identify and clear the alarms.

- Handles and supports multiple vision system cameras, no additional PC required.

- Components’ disassembly and assembly drawings & instructions directly available from the interface.

- Remote support integrated through a secure encrypted router.