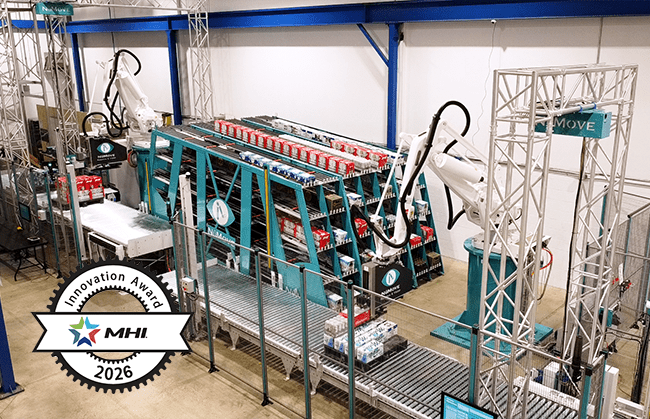

RAPTOR (Robotic Arm Picking to Order Release) is a high throughput dual robot system engineered by NūMove Robotics & Vision in collaboration with KPI Solutions. Designed for the beer and beverage industry, the goal is to automate the building of mixed SKU orders for fast-moving products. This intelligent, automated approach boosts efficiency, accuracy, and flexibility in modern warehouse operations. This vision-guided system depalletizes and palletizes multiple product types and format: closed cases, wrapped products in trays or with bottom pad, cartons in trays, returnable shells. The system also supports various types of donor and order pallets.

The process involves two key steps:

NūMove partners with KPI Solutions on large-scale projects to deliver advanced robotic palletizing and depalletizing systems. Typically, NūMove provides automation solutions while KPI oversees full integration. But things are different with RAPTOR!

This innovative robotic concept was co-created by both companies, merging our expertise to bring a bold, market-driven solution that solves a real challenge. By combining NūMove’s cutting-edge automation expertise with KPI’s integration capabilities, we help businesses improve efficiency, reduce reliance on manual labor, and build scalable, future-ready operations.