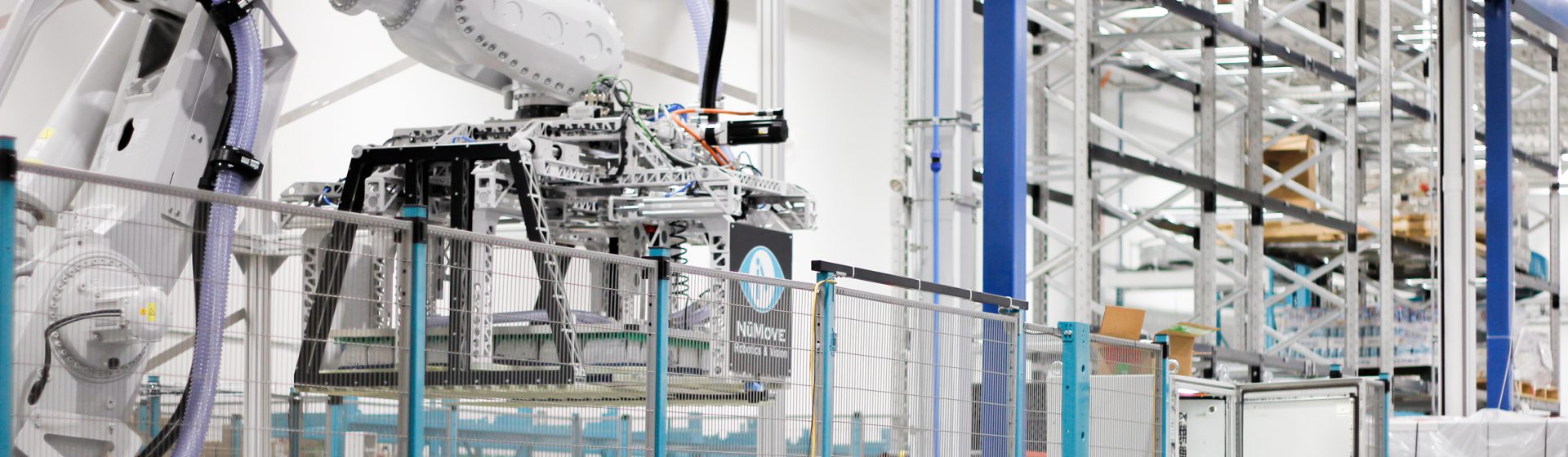

PRODUCT RELEASE — NūMove is proud to introduce its latest innovation in robotics: a newly designed layer picking tool engineered for enhanced adaptability and performance in high-throughput logistics environments. This improved robot tool enables efficient depalletizing of both single-SKU and rainbow pallets.

What Makes This Layer Picking Tool Innovative?

This new depalletizing tool represents a significant advancement over our previous models that relied solely on suction and forks. The latest design integrates three complementary gripping mechanisms — suction, clamping, and bottom forks — enabling the robot to securely handle a broader range of packaging types and formats. These include closed cases, open cases, wrapped or unwrapped trays, and carton boxes in a tray. To avoid product damage, sensors are verifying that the layer is properly lifted before the bottom forks are extended.

How Does This Tool Improve Performance and Reliability For Depalletizing?

The combination of these mechanisms ensures reliable and secure operation across diverse product types, even at high speeds. The suction system is capable of picking partial layers and different layer arrangements that can have gaps, chimneys, etc. The clamping system is ideal for trayed items, while the bottom forks provide additional support to prevent product loss during rapid movements.

Technical Specifications of NūMove’s Layer Picking Tool

- Layer dimensions: 30″ x 36″ to 44″ x 52″

- Layer height range: 2″ to 20″

- Maximum payload capacity: Up to 600 lbs per layer

- Operational throughput: 3 layers per minute, equating to up to 2,000 products per hour (depending on the number of products per layer).

Enhanced Precision with Vision System Integration

To further enhance layer picking precision, the tool can be paired with a vision system that enables the robot to accurately locate the layer’s position, even if the top products have shifted during handling. In line with NūMove’s integrated approach to robotic cell development, peripheral equipment can be added to deliver a complete and optimized solution. For example, downstream conveyors can be incorporated to ensure that all products exit the cell short side leading and single filed.

To conclude, this innovative end-of-arm tool for depalletizing reflects NūMove’s commitment to delivering high-performance, reliable and flexible automation solution tailored to the evolving needs of modern logistics operations.